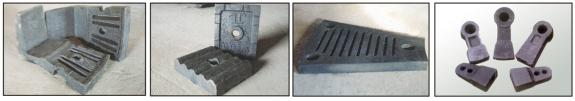

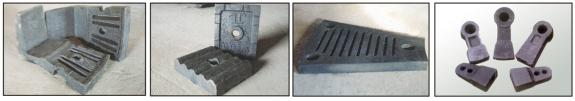

Iipleyiti zentsimbi yokusila imveliso yokusila kukukhusela isilinda sokubetha ngokuthe ngqo ukusuka kwindawo yokusila kunye nezinto eziphathekayo kunye nokukhuhlana, kunokusebenzisa uhlobo olwahlukileyo lwebhodi yomgca ukunyenyisa intshukumo yomzimba wokusila, ukwandisa i-medium yokusila kwisiphumo sokutyumza izinto, inceda ekuphuculeni ukusebenza kakuhle kwelitye lokugaya, ukwandisa imveliso, ukunciphisa ukusetyenziswa kwesinyithi.

Ibhodi yokusila yebhola yasekhaya ngokuthe ngcembe ithathelwe indawo yintsimbi yentsimbi ekwintsimbi ephezulu yemanganese, kodwa njengepleyiti yentsimbi ekuqhubekekeni kokufakwa kwe-ball liner, ithe kancinane endaweni yentsimbi yemanganese kunye nenye ibhodi yomgca ukuze ibe luphuhliso lwemarike olungundoqo.

I-Cylinder liner ngaphezu kokukhusela umzimba, nayo inefuthe ekuhambeni kokugaya i-medium, ukwenzela ukuba ihambelane nemeko yokusebenza eyahlukeneyo (ukugaya kunye nokugaya kakuhle), ukumila kwezinto zokugqoka kukwahluke.Xa i-smash, sinesicelo esinamandla sokuba i-lining surface yokusila ikhono lomzimba lomelele, kwangaxeshanye i-lining kufuneka ibe nokuchasana kwempembelelo elungileyo, Xa inikwa kuqala ukugaya kakuhle, ibhodi yomgca incinci, umsebenzi womzimba wokusila ibuthathaka, impembelelo incinci, kwaye umphumo wokugaya unamandla, ibhodi ye-lining inokumelana nokunxiba kakuhle.